SA301/SA401 Details

MMC is a High performance casting in which SiC ceramic particles are uniformly dispersed in aluminum alloy.

Features

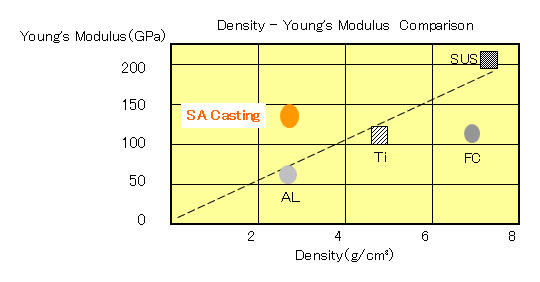

Lightweight ・ High rigidity=High Specific Stiffness

Density → Equivalent to aluminum : 2.8~2.9 g/cm3

Rigidity → Higher than cast iron : 125~150 GPa

Low thermal expansion ・ High thermal conductivity

Thermal expansion is equivalent to carbon steel and stainless steel

Thermal conductivity is higher than aluminum.

By casting methord

It can be replaced with the same shape as aluminum casting, or iron casting.

Manufacture of large complex shape products (500 kg, 2m×2m or more) is possible.

With our own processing machine,

We consistently handle from casting to final shape processing.

Basic properties

| Material | MMC | Aluminum casting | Iron casting | Stainless SUS304 | |

|---|---|---|---|---|---|

| SA301 | SA401 | ||||

| Density (g/cm3) | 2.8 | 2.9 | 2.7 | 7.3 | 7.9 |

| Young's Modulus (GPa) | 125 | 150 | 80 | 115 | 210 |

| Specific rigidity | 45 | 52 | 30 | 16 | 27 |

| Thermal Expansion (x10-6/K) | 14 | 13 | 20.0 | 9.8 | 17.3 |

| Thermal Conductivity (W/m・K) | 150 | 155 | 125 | 50 | 15 |

※The above property values are not guaranteed values.

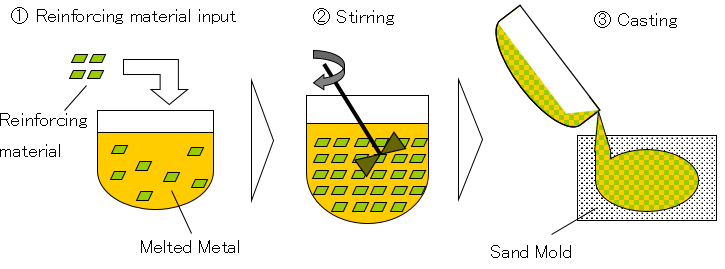

Manufacturing method

Applications

- It is used for precision machinery or inspection equipment parts that requires light weight and high rigidity, or that needs to move and stop at high speed.

-

LCD manufacturing equipments

Semiconductor manufacturing equipments

Chip mounters

High speed press machines

Machine tools

Environment and ECO field

Various production facilitiesMMC are widely adopted in various fields.

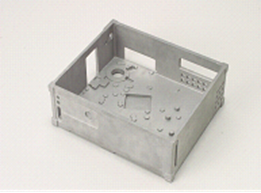

Adopted Product Examples

Lightweight casting case (For measuring instruments)